What is PCB ?

A printed circuit board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads and other features etched from copper sheets laminated onto a non-conductive substrate. PCBs can be single sided (one copper layer), double sided (two copper layers) or multi-layer (outer and inner layers). Multi-layer PCBs allow for much higher component density. Conductors on different layers are connected with plated-through holes called vias. Advanced PCBs may contain components – capacitors, resistors or active devices – embedded in the substrate.

The Process of Making a PCB Board ?

a. Start with a schematic

b. Layout PCB

c. Convert PCB File to Gerber File

d. Send to PCB Factory for sample production

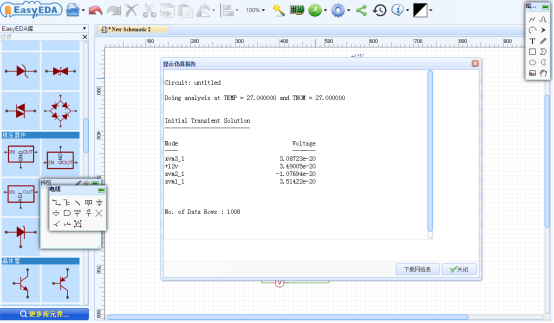

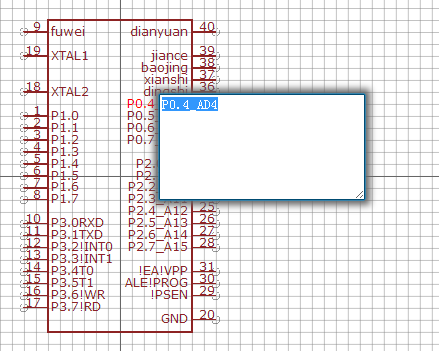

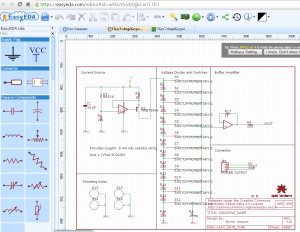

1. Design Schematic , on EasyEDA , for example , design an Atmega16 simpliest system .

1.1 Create a Project . Document -New -Project

1.2 Create a Schematic and start designig a simplest system of MCU .

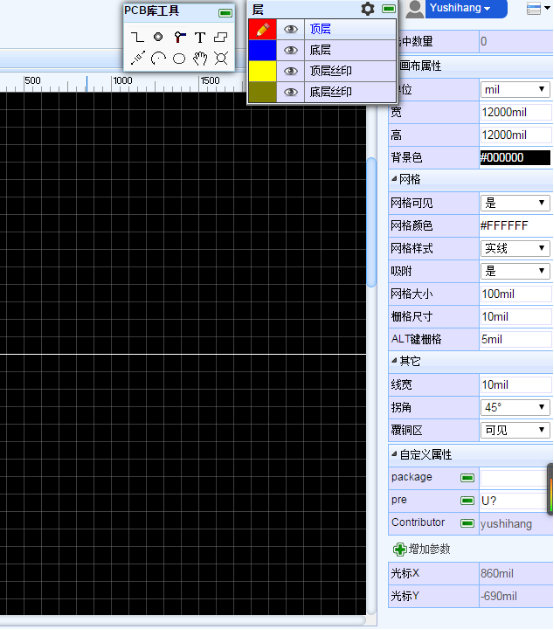

2. Make a PCB

2.1 Convert schematic to PCB and then Place the components in the proper position inside the Mechanical framework :

2.2 Start Routing a PCB manually .

2.2.1 Tips to Make PCB Circuit Board:

Sizing Traces

Real-world copper traces have resistance. This means that a trace has a voltage drop, power dissipation, and a temperature rise when current flows through it. Resistance is defined by this formula:

R=(resistivity∗length)(thickness∗width)

PCB designers most commonly use length, thickness, and width to control the resistance of a PCB trace. Resistance is a physical property of the metal used to make the trace. PCB designers can’t really change the physical properties of copper, so focus on the trace size, which you can control.

PCB trace thickness is measured in ounces of copper. One ounce of copper is the thickness we would measure if we evenly spread 1 oz of copper over a 1 square foot area. This thickness is 1.4 thousandths of an inch. Many PCB designers use 1 oz or 2 oz copper, but many PCB manufacturers can provide 6 oz thickness. Note that fine features like pins that are close together are hard to make in thick copper. Consult your PCB manufacturer about what their capabilities are.

Use a PCB trace width calculator to determine how thick and wide your traces should be for your application. Aim for a 5°C temperature rise. If you have extra space on the board, use bigger traces, as they don’t cost anything.

When doing a multi-layer board, remember that traces on external layers have better cooling than traces on internal layers because the heat from inner layers has to travel through layers of copper and PCB material before being conducted, radiated, or connected away.

Make Loops Small

Loops, especially high frequency loops, should be made as small as possible. Small loops have lower inductance and resistance. Placing loops over a ground plane further reduces inductance. Having small loops reduces high frequency voltage spikes caused by

V=Ldidt

. Small loops also help reduce the amount of signals that are inductively coupled into the node from external sources, or are broadcast from the node. This is what you want, unless you’re designing an antenna. Also keep loops small for op-amp circuits to prevent noise from being coupled into the circuit.

Decoupling Capacitor Placement

Place decoupling capacitors as near as possible to the power and ground pins of integrated circuits to maximize decoupling efficiency. Placing capacitors farther away introduces stray inductance. Multiple vias from the capacitor’s pin to a ground plane reduce inductance.

Kelving Connections

Kelvin connections are useful for measurements. Kelvin connections are made at the exact points to reduce stray resistance and inductance. For example, Kelvin connections for a current sense resistor are placed exactly at the resistor pads, not at some arbitrary place on the traces. Although on the schematic, placing the connections at the resistor pads or at some arbitrary point may look the same, real traces have inductance and resistance that could throw your measurements off if you don’t use.

Keep Digital and Noisy Traces Away from Analog Traces

Parallel traces or conductors form a capacitor. Placing traces close together capacitively couples the signals on the traces, especially if the signals are high frequency. Keep high frequency and noisy traces away from traces that you don’t want noise on.

Ground is not ground

Ground is not an ideal conductor. Take care to route noisy grounds away from signals that need to be quiet. Make ground traces large enough to carry the currents that will flow. Placing a ground plane directly under signal traces lowers the impedance of the traces, which is ideal.

Via Size and number

Vias have inductance and resistance. If you’re routing a trace from one side of the PCB to the other and need low inductance or resistance, use multiple vias. Large vias have lower resistance. This is especially useful in grounding filter capacitors and high current nodes.

Thermal vias

Vias can be used to move heat from one side of a PCB to the other. This is especially useful when a PCB is mounted on a heatsink on a chassis that can further dissipate heat. Large vias transfer heat more efficiently than small vias. Many vias transfer heat more efficiently than one via, and lower the operating temperature of components. Lower operating temperatures contribute to higher reliability.

Distances between traces and mouting holes.

Leave room between copper traces or fills and mounting holes; this helps prevent shock hazards. Solder mask isn’t considered a reliable insulator, so take care that there is distance between copper and any mounting hardware.

Heat sensitive components

Keep components that are sensitive to heat away from other components that generate heat. Examples of components that are sensitive to heat include thermocouples and electrolytic capacitors. Placing thermocouples close to heat sources may throw off temperature measurements. Placing electrolytic capacitors close to heat generating components will reduce their operating life. Components that generate heat may include bridge rectifiers, diodes, MOSFETs, inductors, and resistors. The heat depends on current flowing through the components.

Width of Trace :

The minimum width of trace is 4 mil when you layout very simple circuits ,and when you layout the current traces , you need to consider the width of Traces. Here with the relationship between the Trace width and the current .

Copper Thickness

35UM 50UM 70UM

Width Current Width Current Width Current

0.15 0.20 0.15 0.50 0.15 0.70

0.20 0.55 0.20 0.70 0.20 0.90

0.30 0.80 0.30 1.10 0.30 1.30

0.40 1.10 0.40 1.35 0.40 1.70

0.50 1.35 0.50 1.70 0.50 2.00

0.60 1.60 0.60 1.90 0.60 2.30

0.80 2.00 0.80 2.40 0.80 2.80

1.00 2.30 1.00 2.60 1.00 3.20

1.20 2.70 1.20 3.00 1.20 3.60

1.50 3.20 1.50 3.50 1.50 4.20

2.00 4.00 2.00 4.30 2.00 5.10

2.50 4.50 2.50 5.10 2.50 6.00

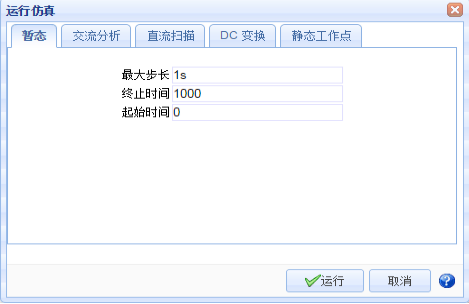

Laying out DC-DC voltage Circuits .

Laying out a DC-DC circuits , it should obey very strict rules according to the DC-DC Converter Datasheet .

Laying out High Speed Circuits and differential Circuits .

Laying out High-speed circuits also require designers to consider its impedance matching .And for the differential circuits we should parallel the wires and make impedance matching through a GND Layer or Power Layer. Every High-Frequency circuits requires impedance matching should be provided with a referential Layer .

Keep Noisy Circuits away from High-Speed Circuits

Noisy circuits too close to High-Speed circuits may cause the the High-Speed singal to distortion and affect normal operation of High-Speed circuits .

2.2.2 The Result of the MCU PCB Layout .

2.2.3 Pour the Copper on the BottomLayer .

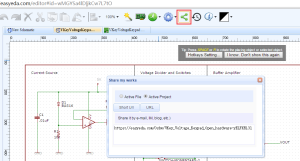

https://easyeda.com/GerryChen/MCU_Project-HFzQ82kCU

https://easyeda.com/GerryChen/MCU_Project-HFzQ82kCU

3. Click the Photo view to check the Gerber file

4. Send Gerber file to PCB factory for PCB production and debug the the circuits by welding the components and ICs . That is a complete process of Making PCB board and Testing 、Debuging the circuits .

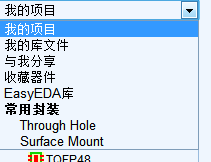

5. Easyeda Provides an cheap PCB Cart which offers low-price PCB and improve your efficiency to Make PCB .

Easyeda provides an Fabrication Output function . By clicking it , You can add the pcb order to cart and order the pcb board . You could wait at home or your company for the PCB and weld components at home or send to be welded by factory ,especially ICs with BGA Package .

Easyeda provides a one-stop shop for Electronics projects .You could go to it and experience designing Schematic & PCB and order PCB .

Source: https://easyeda.com/GerryChen/How_to_Make_PCB_on_Easyeda_-HFzQ82kCU

——The Register and Login Interface .

——The Register and Login Interface . ——The mainpage of

——The mainpage of  ——The diagram of the Editor

——The diagram of the Editor ——A Led Light Schematic Example .

——A Led Light Schematic Example .

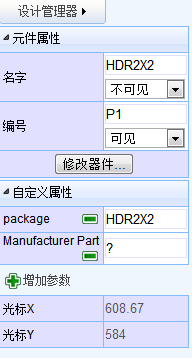

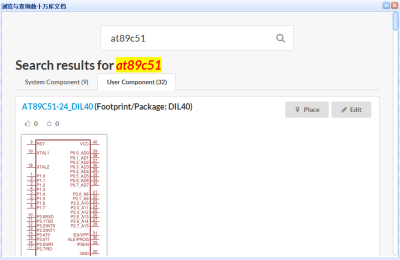

——Choose the Package for the component and preview.

——Choose the Package for the component and preview. ——The effect of Auto Routing1

——The effect of Auto Routing1 ——The Effect of Auto Routing2.

——The Effect of Auto Routing2. ——The Effect of Photo Preview

——The Effect of Photo Preview